The solution for Processes up to 1,000°C

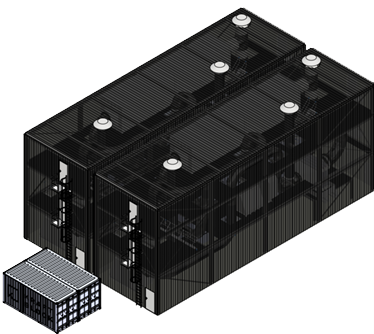

Excess electricity is converted into heat with 98% efficiency and stored for up to two weeks. The storage system uses the energy to generate heat transfer media such as steam and to heat transfer media such as thermal oil, water or drying air. That way, any production using heat can be 100% decarbonized with just one step - replacing the burner.

Over 70% of the world's heat consumption in the temperature range of 100-400 degrees Celsius is generated by oil, gas or coal. Fossil energy can be replaced by renewable energy. The Kraftblock Net-Zero Heat solution is the right system for this transition.